ATEX is an abbreviation for the French designation “ATmosphères EXplosibles”. This can be found in the European Union’s Directive 2014/34/EU, which defines the legal basis for the use of equipment and protective devices in areas with potentially explosive atmospheres. The ATEX Directive is an essential component of explosion protection that is applied in all areas of industry, including the chemical and pharmaceutical industries.

Compliance with the ATEX directive is essential to ensure safety in environments with potentially explosive atmospheres. The directive stipulates that equipment and protective systems must be designed, manufactured and tested in such a way that they do not endanger the safety of people or the environment in the event of an explosion.

A key aspect of explosion protection in accordance with ATEX is the classification of potentially explosive atmospheres into zones. This classification helps to determine the necessary protective measures for devices and systems that are used in these zones. Depending on the frequency and duration of the occurrence of an explosive atmosphere, areas are divided into zones 0, 1 or 2 for gases, vapors and mists and into zones 20, 21 or 22 for dusts.

Excursus: When do explosions occur?

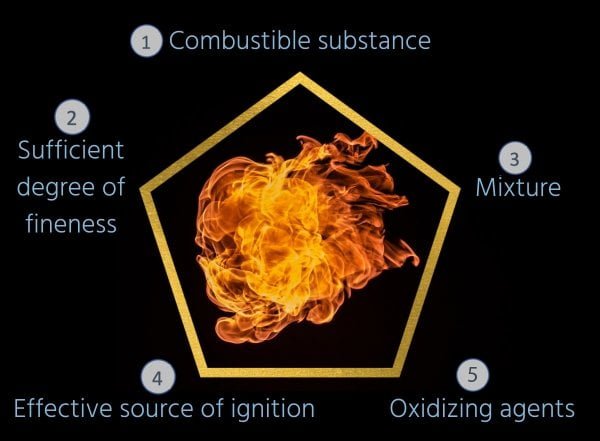

Explosions in industry are an omnipresent hazard as soon as explosive substances and mixtures are used. These substances and mixtures can be solid, liquid or gaseous. The conditions that must be met for an explosion to occur are illustrated by the hazard pentagon.

Assessing the risk of explosion: The hazard pentagon

The hazard pentagon shows all components necessary for an explosion: If these are present at the same time, an explosion can occur. If, on the other hand, only one of the five conditions is missing, the explosion hazard is no longer present.

In order to assess the risk and effects of an explosion in principle, the substances used are evaluated using explosion indicators. These are important for making decisions regarding protective measures and usable equipment located in the hazardous area.

Explosion indicators are intended to help assess the risk of explosion. There are a wide variety of figures that need to be taken into account. You can find an overview of the most important explosion figures for dust in the table in the blog article of the same name.

Classification in ATEX zones

Production facilities and plants with potentially explosive atmospheres are divided into explosion protection zones(ATEX zones), which are recorded in the explosion protection document. This classification of the zones is carried out on the one hand by the manufacturer of the systems and devices and on the other hand by the operator of the production facilities in which the systems are used. There are dust and gas Ex zones, depending on the composition and duration of occurrence of the explosive substances and mixtures, as well as groups and categories for assessing the equipment. These determine the respective requirements for the necessary protective measures in the respective areas. We have dedicated a separate blog article to the differences and the assignment of equipment categories to ATEX zones.

What must be observed when dealing with the specifications from the ATEX directive?

In order to guarantee the highest possible safety for the workers as well as the plant also from the legal side, there are various ATEX regulations and directives that must be observed. A distinction is made here between the directives for the operator of the equipment with potentially explosive atmospheres and for the manufacturer of this equipment. There are European as well as national directives and regulations that must be observed.

If explosive atmospheres are present, special care must be taken! However, plant operators and manufacturers can protect themselves not only by complying with the legal requirements. You can take further protective measures, which can be both preventive and constructive. Thus, there are preventive types of protection, which are intended to prevent the explosion, but likewise constructive protective measures, which are intended to minimize the damage to the plant.

Conclusion

Explosions can occur as soon as flammable substances come into contact with reaction substances. Industries and production areas with an increased probability of explosion must take protective measures based on legal requirements. There are measures for the plant operator and the plant manufacturer. In order to be able to take suitable protective measures for the operation or the plant, explosion characteristics must be determined beforehand. These help, in connection with the present ATEX zones, to protect the endangered space in the best possible way against an unwanted explosion.