The cleanable filter system for highest demands

The cleanable HEPA filter system

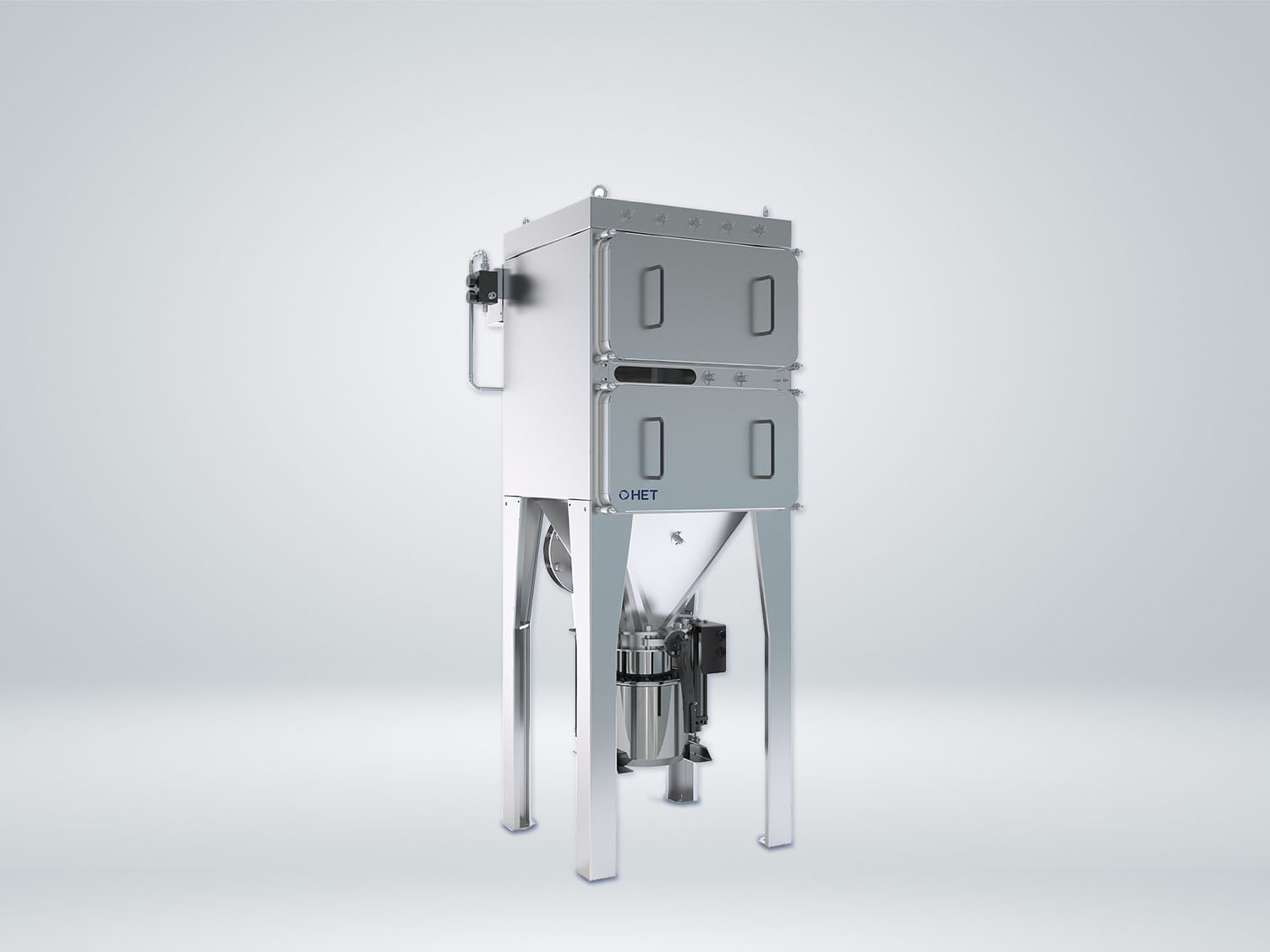

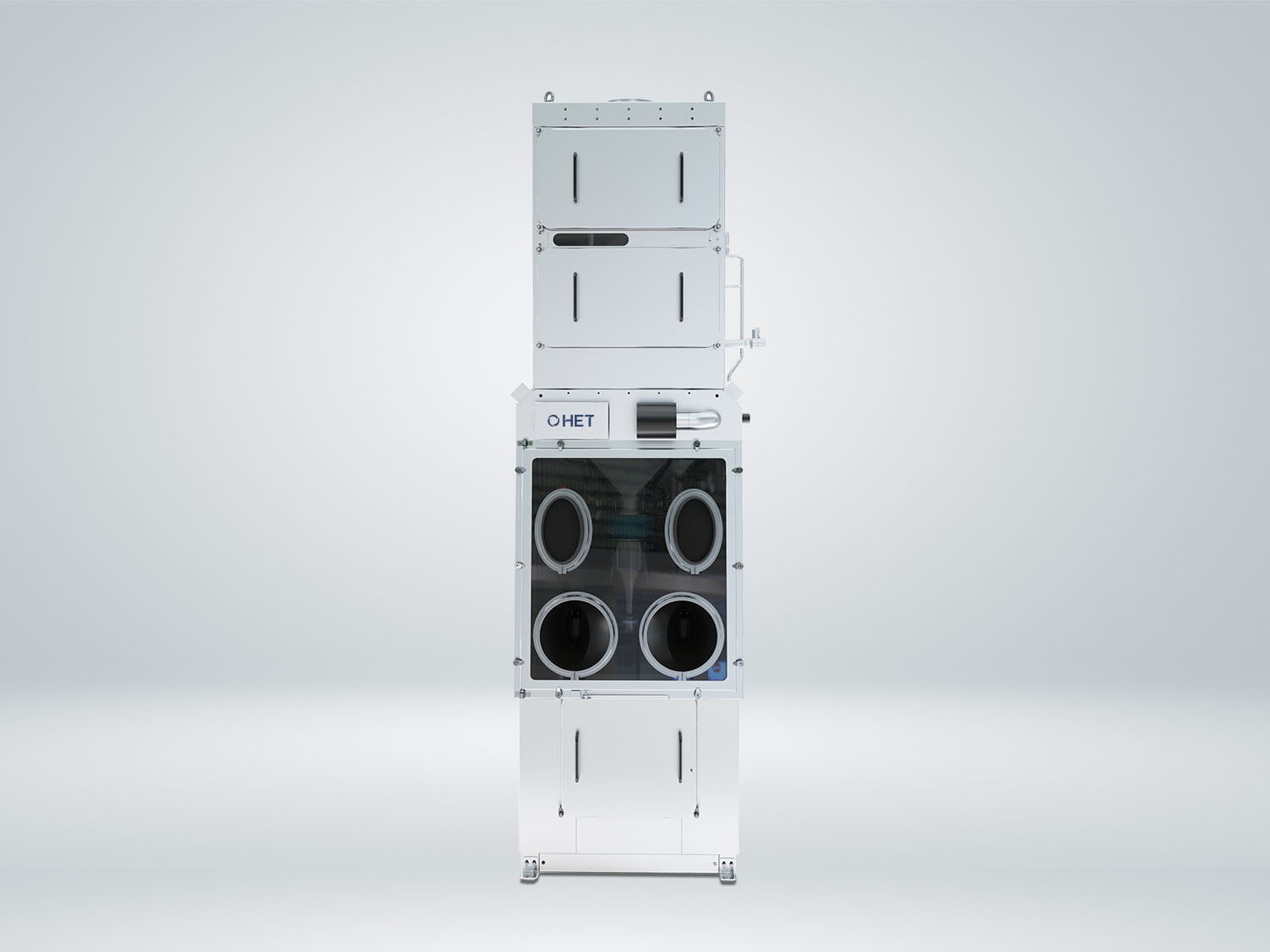

With the HETdynamic HEPA filter system, we offer an advanced solution that is specifically designed to meet the requirements of modern industries. It is ideal for environments where dust concentrations of 5 mg/m³ or more can occur. The HETdynamic is characterized by an internal HEPA filter cell, which plays a key role in the efficiency and economy of the system. This filter cell has an automatic regeneration system that is activated as soon as the dust load exceeds a certain threshold value. This self-cleaning function not only ensures a longer service life for the filter, but also significantly reduces the need for maintenance work and filter changes.

The HETdynamic is designed to work continuously – it can operate without interruption 24 hours a day, 7 days a week, 365 days a year. This reliability makes it an optimal choice for industries that require uninterrupted air purification.

Another feature of the HETdynamic is the efficient use of the filter surface. Automatic regeneration after each extraction process allows the system to clean the same volume flow with a significantly reduced filter area, which increases efficiency and reduces operating costs at the same time. These features make the HETdynamic an ideal choice for demanding applications where a powerful HEPA filter system is required to ensure a clean and safe working environment.

HETdynamic

Advantages

- Safe containment up to OEB 6

- Double HEPA filtration

- Highest explosion protection

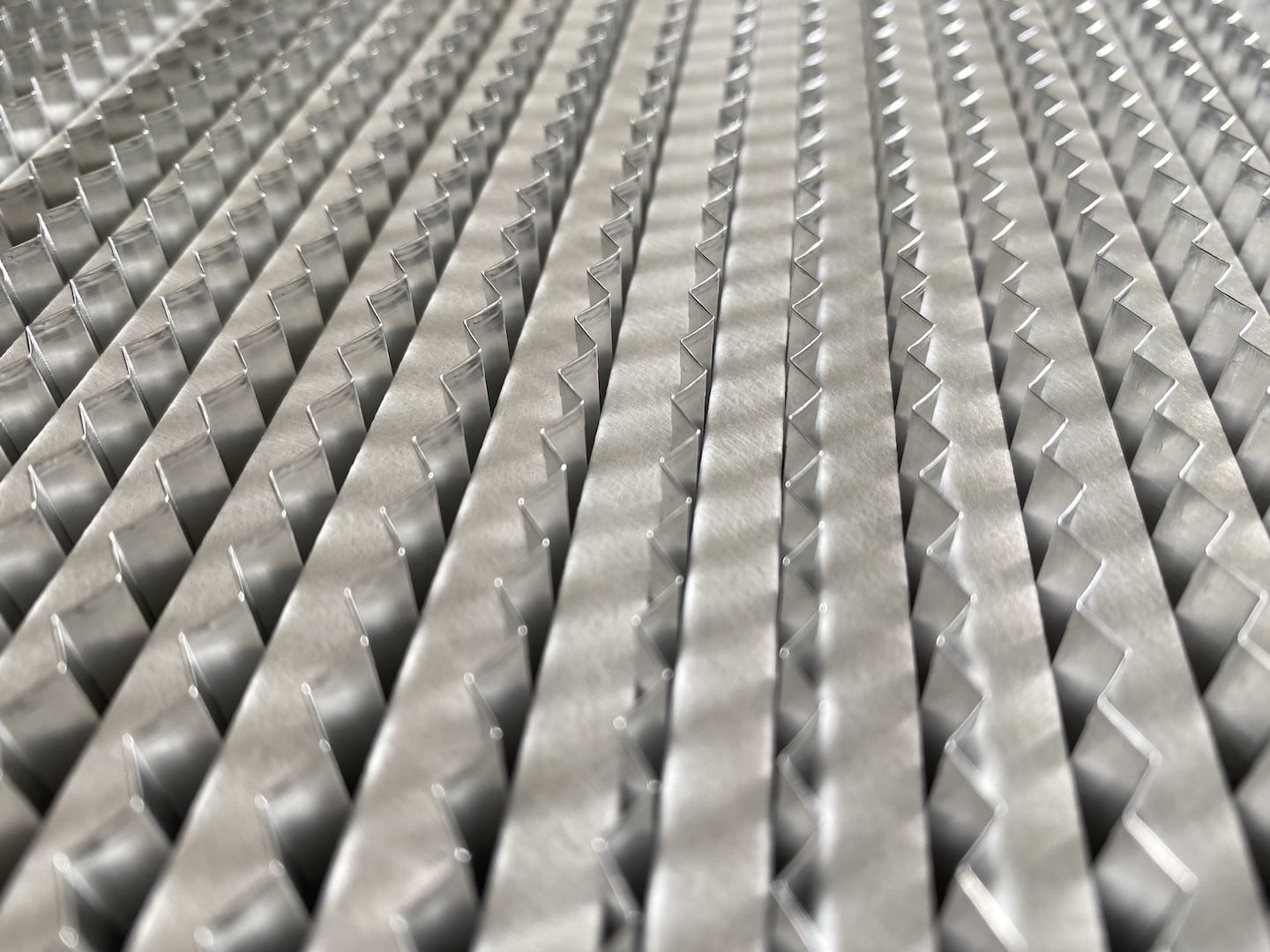

- Cleaning system for backwashing the primary filter by means of cleaning cylinder

- Continuous and discontinuous operation

- Plant in dust-tight or gas-tight design

- DEHS measuring points for qualification of the safety filter stage

- GMP-compliant design

Features

Tightness tested

Highest containment level due to safe filter replacement

Highest explosion protection

We are happy to advise you

Get in touch with us

Simone Knasel

TECHNISCHE INFORMATION

Options

Technologies

Filtration

Containment

Explosion protection

other filter systems

The mobile small dust collector

Filter system for low dust loads

HEPA filter for highest demands

Mobile small dust extractor for flexible use

Filter systems for low dust loading

HEPA filter for highest demands