Containment

Our containment technology provides safe protection against hazardous substances.

Our containment technology

For safe protection against highly active substances

In the pharmaceutical industry, where the demands on filter technology are particularly high, containment plays a crucial role in ensuring both product quality and the safety of personnel. Containment systems are designed to control and isolate hazardous dusts and particles throughout the manufacturing process. This is particularly important in order to protect the environment from contamination not only during operation, but also during maintenance and servicing work, such as a filter change.

Our filter technologies integrate advanced containment solutions to guarantee seamless protection. During operation, these systems ensure that no hazardous or toxic substances can escape from the production environment. When carrying out maintenance work, our containment systems offer additional safety mechanisms to minimize the risk of exposure to hazardous substances.

In addition, the integration of containment strategies into our filter systems is proof of our commitment to meeting the highest safety and protection standards. We understand that containment is more than just a technical requirement – it is a fundamental component that ensures the protection of people and products throughout the pharmaceutical production process. By continuously developing our containment technologies, we ensure that our customers can rely on the most effective and secure filter solutions.

Integrated systems

For highest employee protection

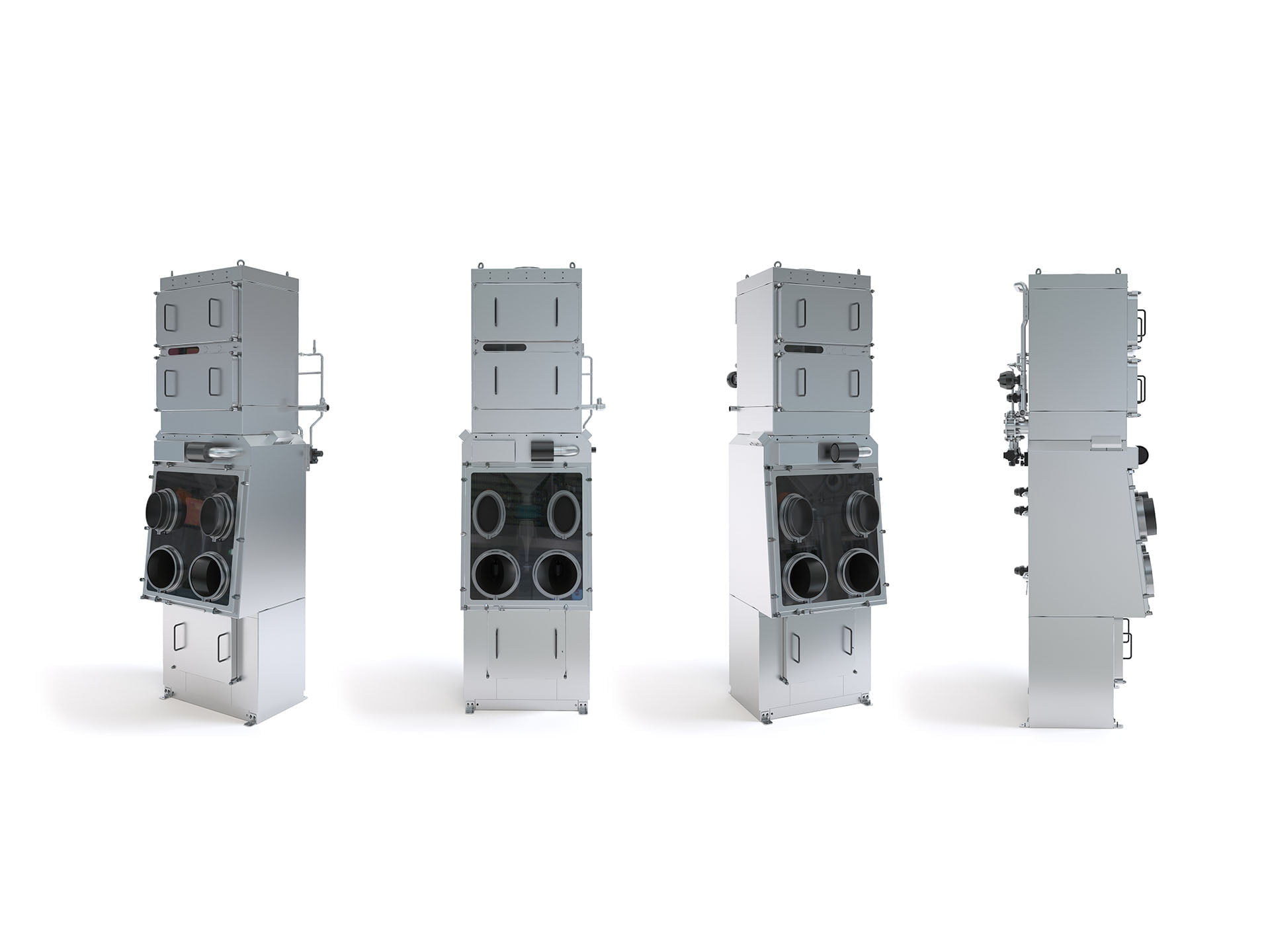

Our HETdynamic, equipped with WIP (wash-in-place) and Rabs (restricted-access barrier system) features, gives you a high level of protection with very low workplace concentration. It was specially developed for the application of highly effective products and is explosion pressure shock resistant. For this, like any of our equipment, it does not require additional pressure relief.

The HETdynamic becomes usable in the category OEB 5 by the features WIP and Rabs and thus offers a maximum workplace exposure of <1μg /m3.

WIP and Rabs

offers you the highest level

an Containment

- Wash-in-place system

- Rabs (Glovebox)

- Safety requirement OEB5

- Dust contact-free change of protective bag

by means of safe-change system for filter and dust discharge

- Clean gas values up to 0.001 mg/m

3

- Conductive and explosion pressure shock resistant versions

- Version with primary filter (working filter) and secondary filter (safety filter)

- GMP compliant design

Filtration

Ensures clean air

learn more

Explosion protection

for maximum safety

learn more

HETservices

Profit from our know-how

Rely on our service and let us work together to find a customized solution for your filter requirements!