Potentially explosive atmospheres are divided into corresponding zones – depending on the frequency and duration of the occurrence of hazardous explosive atmospheres. The system operator is responsible for defining the zone for the operation of the system, while the manufacturer is responsible for defining the zone for the system. Ultimately, however, the system operator decides on the zoning.

This zone classification is based on the European ATEX Directive (Atmosphères Explosibles), which defines the requirements for devices and protective systems used in potentially explosive atmospheres. The Atex zones are specifically defined to minimize the risk of explosions and ensure safety standards.

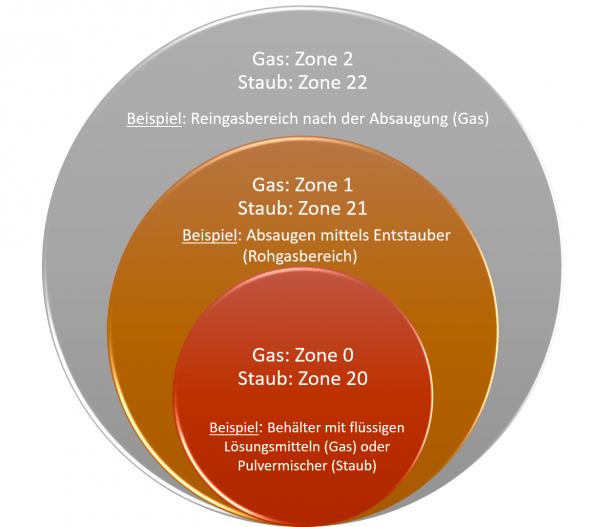

Dust and gas Ex zones

The basis for the classification into zones is the duration of the presence of the potentially explosive atmosphere: the longer this is present, the more critical the zone becomes. A distinction is made between gas Ex zones and dust Ex zones: gas Ex zones are 0/1/2 and dust Ex zones are 20/21/22. In terms of classification, they are the same.

- Zone 0/20: An explosive atmosphere occurs continuously, for long periods or frequently.

- Zone 1/21: An explosive atmosphere occurs occasionallyduring normal operation.

- Zone 2/22: An explosive atmosphere does not occur or is likely to occur in the short term during normal operation.

Device groups and categories

In addition to the division of the areas into Atex zones, there is also a classification of the devices that can be used according to the necessary safety requirements. This classification results from the risk assessment: The manufacturer of devices with a potential ignition source must relate the protective measures for explosion protection to the probability of an explosive atmosphere occurring.

The devices are divided into categories that are matched to the three Atex zones. Category 1 devices are suitable for zone 0 (or 20 for dust), category 2 for zone 1 (or 21 for dust) and category 3 for zone 2 (or 22 for dust). This categorization helps to ensure that only suitable and certified devices are used in appropriately classified areas.

For standard equipment, the testing of a type is an accepted method, provided that the equipment remains in its tested form and no modifications are made to the type. This type examination is usually carried out by a notified body, which performs an EU conformity assessment.

An individual test is required for all other systems or devices that are not covered by the standard version or that have been modified. This test can be carried out either by a notified body or by a specially trained service technician. It must be checked whether the devices and systems meet the specific requirements of the risk assessment and the applicable Atex zones.

According to Directive 2014/34/EU (ATEX), the classification is made into the following equipment groups and categories:

- Unter die Gerätegruppe I fallen explosionsgefährdete Bereiche unter Tage. Die Gefährdung entsteht durch Grubengas und/oder Staub. Darunter fallen die Kategorien M1 und M2:

- The M1 category testifies to a very high level of safety, even when two independent faults occur.

- The M2 category testifies to a high level of safety. The devices switch themselves off when explosive atmospheres occur.

- Unter die Gerätegruppe II fallen explosionsgefährdete Bereiche über Tage. Die Gefährdung entsteht durch Flüssigkeiten oder Gase. Darunter fallen die Gerätekategorien 1,2 und 3:

- Device category 1 indicates a very high level of safety.

The degree of protection is very high for rare faults and when two independent faults occur. - Device category 2 indicates a high degree of safety.

The degree of protection is high in the event of an expected malfunction and fault. - Device category 3 indicates an increased level of safety.

The degree of protection is normal in normal operation.

- Device category 1 indicates a very high level of safety.

- Equipment group III covers potentially explosive atmospheres above ground. The hazard arises from finely dispersed solids (dust).

Assignment of the device categories to the Ex zones

brennbares Medium | Dauer des Vorhandenseins explosionsfähiger Atmosphäre | Ex-Zone | Explosionsgruppe | Gerätekategorie | ||

|---|---|---|---|---|---|---|

| Gase, Dämpfe, Nebeln (G) | ständig, dauernd | Zone 0 | II | 1G | ||

| gelegentlich | Zone 1 | II | 2G | |||

| selten | Zone 2 | II | 3G | |||

| Staub (D) | ständig, dauernd | Zone 20 | II | 1D | ||

| gelegentlich | Zone 21 | II | 2D | |||

| selten | Zone 22 | II | 3D | |||

Dust collector markings

The marking of dust extraction systems subject to 2014/34/EU is carried out

in accordance with EN 80079-36. The marking of a dust extractor in an explosive atmosphere or in operation with explosive dusts or gases must be clearly and indelibly placed on the system, e.g. in the form of a type plate. The labeling must include the following information:

- CE marking, number of the notified body and the EX mark

- Group and the device category within the meaning of the 2014/34/EU

- Protection principle, e.g. Exh=constructive safety

- Gas– bzw. Staubgruppe:

- Gas group IIB contains groups IIB and IIA, but not IIC.

- Dust group IIIA defines combustible lint, dust group IIIB non-

conductive dusts and dust group IIIC conductive dusts

- Temperature range in which the equipment may be used. The definition is made via the process temperature.

- Class: perm. Surface temperature / max. Process temperature

T1: 450°C/360°C ; T2: 300°C/240°C ; T3: 200°C/ 160°C ;

T4: 135°C/108°C ; T5: 100°C/80 °C ; T6: 85°C/68°C

- Class: perm. Surface temperature / max. Process temperature

- Device protection level: indication of the device protection level required for the device category.

- Zone 2 or 22 : Avoidance of ignition sources in normal operation.

Marking: Gc or Dc. - Zone 1 or 21: Avoidance of ignition sources even in the event of normal operating faults.

Marking: Gb or Db. - Zone 0 or Zone 20: Avoidance of ignition sources even in the event of rare operating faults.

Marking: Ga or Da.

- Zone 2 or 22 : Avoidance of ignition sources in normal operation.

- Field for acceptances (if not used, then “/”)

- Einsatzbereich des Geräts

- –: the device can be used without restriction.

- X: there are specific operating conditions that must be described in more detail in the documentation

. - U: incomplete machine, without CE marking

The marking must be indicated separately for dust Ex as well as gas Ex. This means that for hybrid mixtures, two labels must be present on the equipment.

An example labeling for dust collection equipment may look like this:

| Gase/Dämpfe: | CE 0588 |  | II 2/-G | Exh | IIB | T6...T5 | Gb / | - |

| Staub: | CE 0588 |    | II 2/-D | Exh | IIIA | T85°...T100°C | Db / | - |

Conclusion

The classification of the hazard and the division into device categories according to the Atex zones means that different safety concepts are required for the devices and systems used. These safety concepts are essential to ensure the protection of people and the environment in potentially explosive atmospheres. The specific requirements for devices and protective systems are defined in the relevant European standards, which are in line with the ATEX directive.

Knowledge of the processes and substances used is essential in order to carry out an appropriate risk assessment and the correct zoning and equipment categorization. Every device used in an Atex zone must be specially designed and certified for use in this zone. The devices are divided into three main categories corresponding to Atex zones 0/20, 1/21 and 2/22, with category 1 meeting the highest safety requirements.