by Webseitenhelden22 | Feb 9, 2021 | Filter

Wherever dust is generated in the course of the production process, measures must be taken to protect people and the environment by minimizing – if not eliminating – exposure to dust. In accordance with the STOP principle for reducing dust pollution or the...

by Webseitenhelden22 | Jan 4, 2021 | Filter

Dust collectors and filter systems are used in the pharmaceutical and chemical industries to bind the dust generated during production. In the filter cells installed in it, the particles are separated from the air, so that in the end clean air is created and the...

by Webseitenhelden22 | Oct 19, 2020 | Filter

Various processes and production steps are used in the pharmaceutical industry and other branches of industry, all of which have one thing in common: They generate emissions that are subsequently present in the environment and the air we breathe.Depending on their...

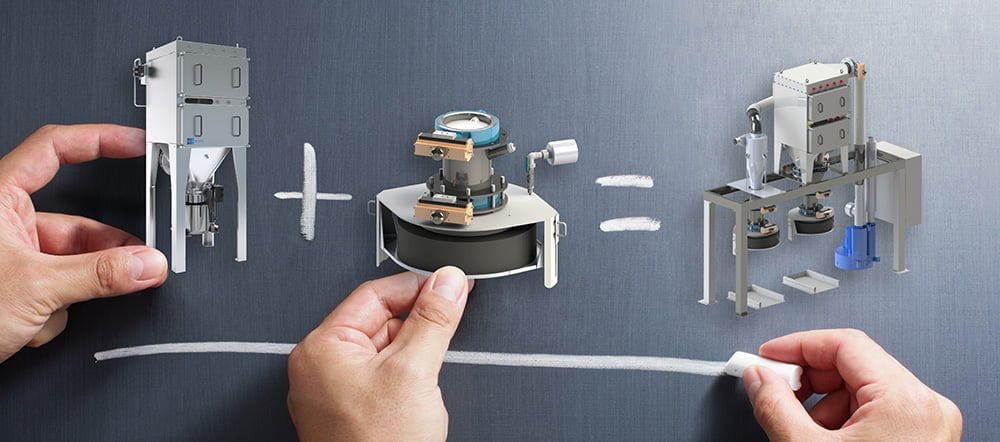

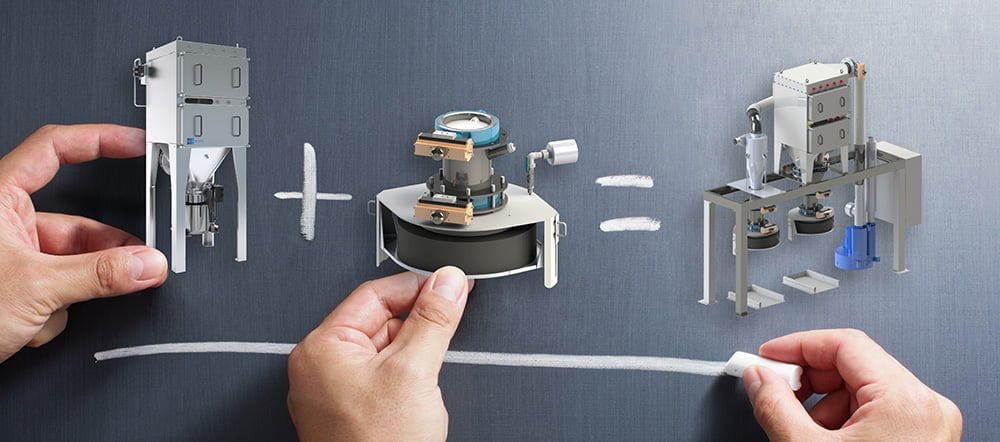

by Webseitenhelden22 | May 28, 2020 | Containment

Hazardous dusts are inevitably encountered in the pharmaceutical industry. Containment measures are implemented to reduce the risk of contamination and thus also provide greater employee protection. The aim of these is to form a protective area for employees and the...

by Webseitenhelden22 | Mar 16, 2020 | Containment

Containment through filter systems – employee protection in the pharmaceutical industry: In many branches of industry, dust is a type of hazardous substance due to its composition and is therefore a major problem. Particularly in the pharmaceutical industry, the...