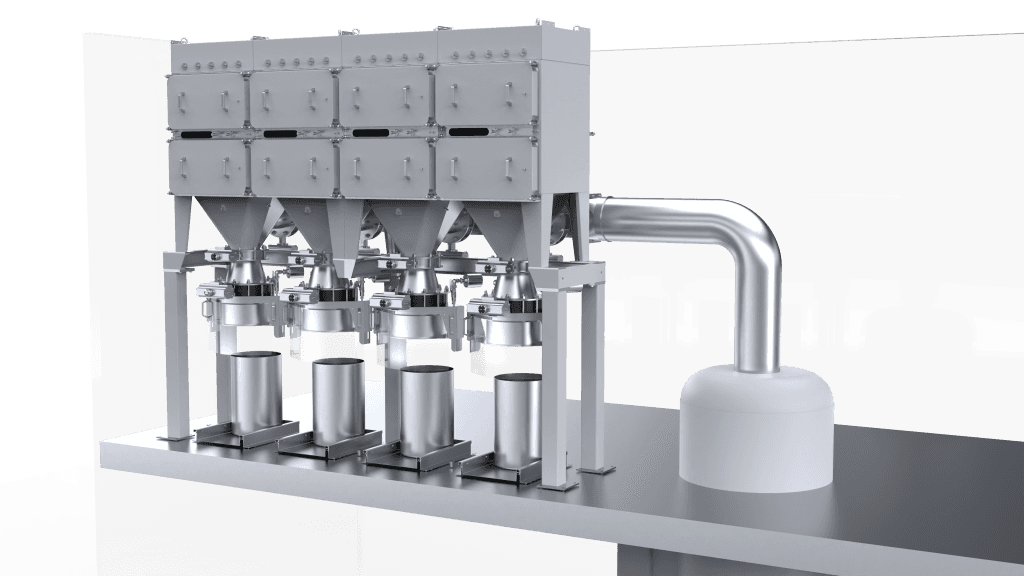

Fluidized beds in the pharmaceutical industry are an essential part of modern production processes. These systems are used for various applications, including the drying, granulation, coating, agglomeration and mixing of powders and granulates. The targeted use of air flows sets the particles in a floating motion, enabling uniform processing. This process ensures precise control of the particle size distribution and a homogeneous coating – both decisive factors for the quality of pharmaceutical products.

An important area of application for fluidized beds in the pharmaceutical industry is drying. Hot air is passed through the material in a controlled manner so that the moisture is efficiently removed. This increases the stability and shelf life of the end product. During granulation, powder particles are formed into uniform granules with the help of binding agents, which are ideal for tableting. Coating also plays an important role: protective layers enable the targeted control of active ingredient release, for example through enteric coatings or taste masking. Agglomeration also improves the flow properties of the granules, which is crucial for precise dosing and further processing.

Challenges in fluidized bed processes in the pharmaceutical industry

Despite their efficiency, fluidized beds pose specific challenges in the pharmaceutical industry. The intense airflow required for fluidized bed processes whirls up a large amount of fine powder particles. These particles can impair product quality, pollute the production environment and pose a risk to the health of employees.

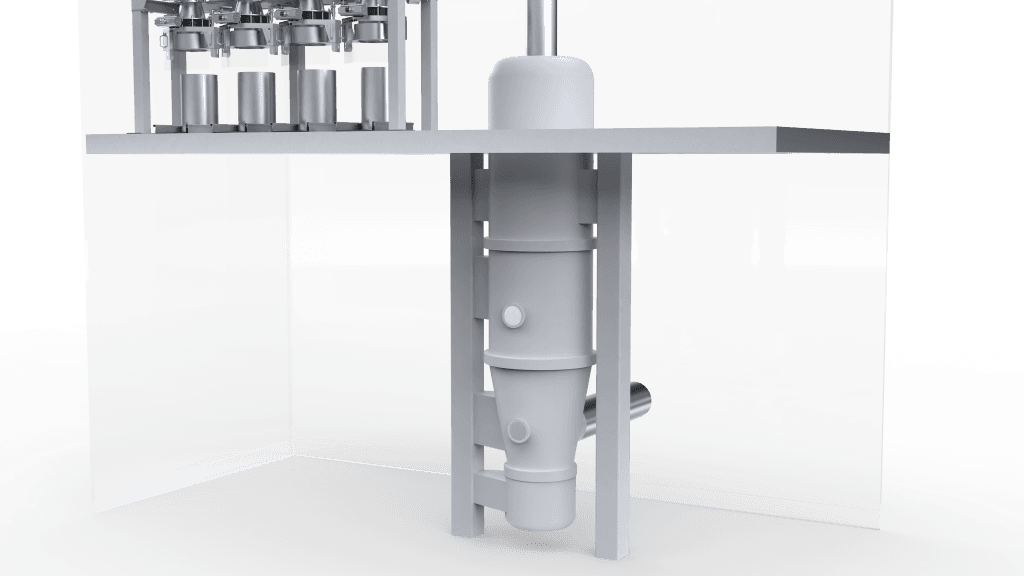

High-performance filtration systems are essential to minimize these risks. HEPA filters offer an efficient solution here, as they remove at least 99.95% of all particles with a size of 0.3 micrometers from the air. This filter technology meets the strict requirements that apply to clean rooms in pharmaceutical production.

The use of HEPA filters is essential for fluidized bed filters in the pharmaceutical industry, as they play a crucial role in reducing dust pollution. These filters ensure that whirled-up particles do not enter the production environment, which ensures the quality of pharmaceutical products and protects employees from potentially harmful substances. Especially when processing highly potent active ingredients, effective filtration is crucial to ensure compliance with the statutory OEL limits (Occupational Exposure Limits).

HEPA filters also prevent cross-contamination, which can occur when different active ingredients are processed in the same production system. They also protect downstream systems such as pipelines, fans and heat exchangers from dust deposits. These deposits can lead to a loss of efficiency and increased maintenance, which has a negative impact on operating costs.

The advantages of cleanable HEPA filters for the fluidized bed pharmaceutical industry

Cleanable HEPA filters offer decisive advantages for fluidized beds in the pharmaceutical industry. Unlike conventional filter systems, these regenerate themselves regularly, which extends the service life of the filter media and reduces the need for frequent filter changes. This lowers operating costs and ensures longer, trouble-free production cycles.

A significant advantage of cleanable filters is the stabilization of the air flow. Regular cleaning keeps the pressure loss in the system constantly low, which ensures stable process conditions. These filters also contribute to sustainable production, as they generate less waste and therefore also reduce disposal costs.

Regulatory requirements for filtration in the pharmaceutical industry

The use of fluidized beds in the pharmaceutical industry is subject to strict regulatory requirements designed to ensure safety, product quality and environmental compatibility. Compliance with these standards is crucial to ensure the quality of production processes and to meet legal requirements.

The most important regulatory requirements include

Compliance with OEL limits (Occupational Exposure Limits)

These limits define the maximum permissible exposure to certain substances in the air we breathe. Effective filtration protects employees from contact with highly potent active ingredients that are processed in pharmaceutical production.

EU GMP guidelines

EU GMP (Good Manufacturing Practice) requires clear measures to prevent cross-contamination and ensure product purity. The use of HEPA filters is a key component in achieving the required air purity in production areas.

ATEX directives

These regulations apply to potentially explosive atmospheres. In processes where explosive dusts may be generated, all filtration systems must comply with ATEX requirements in order to ensure the safety of production facilities.

Sustainability and increased efficiency through modern filtration technology

Modern HEPA filtration systems not only offer advantages in terms of safety and quality for fluidized beds in the pharmaceutical industry, but also economic benefits. Cleanable filters reduce operating costs as they have a longer service life and extend maintenance intervals.

In addition, these filter systems contribute to sustainable production as they minimize energy consumption. The stable air flow ensures that processes run efficiently without the need for additional energy input to maintain the pressure conditions. In addition, the service life of the entire system technology is extended as dust deposits in the exhaust air systems are avoided, which reduces maintenance costs.

The combination of modern filtration technology and efficient fluidized bed production is a key success factor for companies in the pharmaceutical industry. Cleanable HEPA filters ensure maximum safety, extend the service life of filter systems, reduce operating costs and meet all regulatory requirements.

The targeted use of efficient filtration not only ensures product quality, but also protects the health of employees and minimizes environmental impact. Companies that invest in modern HEPA filter systems benefit from a smooth, efficient and sustainable production process.

Find out more about our filter systems for fluidized beds and optimize your production processes with the latest filtration technology from HET Filter.