The pharmaceutical industry faces constant challenges to ensure the highest quality standards, meet strict regulatory requirements and at the same time optimize production costs in the pharmaceutical industry. A decisive aspect in this context is the choice of the right containment system, particularly in the manufacture of highly effective active ingredients and medical products. Containment systems play a central role in ensuring both employee safety and product purity. The right choice can not only improve efficiency and safety, but also enable significant savings in production costs.

How does the choice of the right containment system affect production costs?

Increased safety and reduced downtime

An effective containment system minimizes the risk of contamination and accidents that can lead to production interruptions. This avoids expensive downtime and possible penalties from regulatory authorities.

Optimized cleaning processes

Modern containment systems are designed to be easy to clean and maintain. This reduces the time and cost of cleaning procedures and enables production to be resumed more quickly after product changes.

Reduced consumption of protective clothing and equipment

The use of effective containment systems can significantly reduce the need for personal protective equipment (PPE) for employees. This reduces the ongoing costs for the procurement and disposal of PPE.

Improved product quality and fewer rejects

A well-designed containment system ensures consistently high product quality by preventing cross-contamination and impurities. This results in fewer rejects and a higher yield of saleable products.

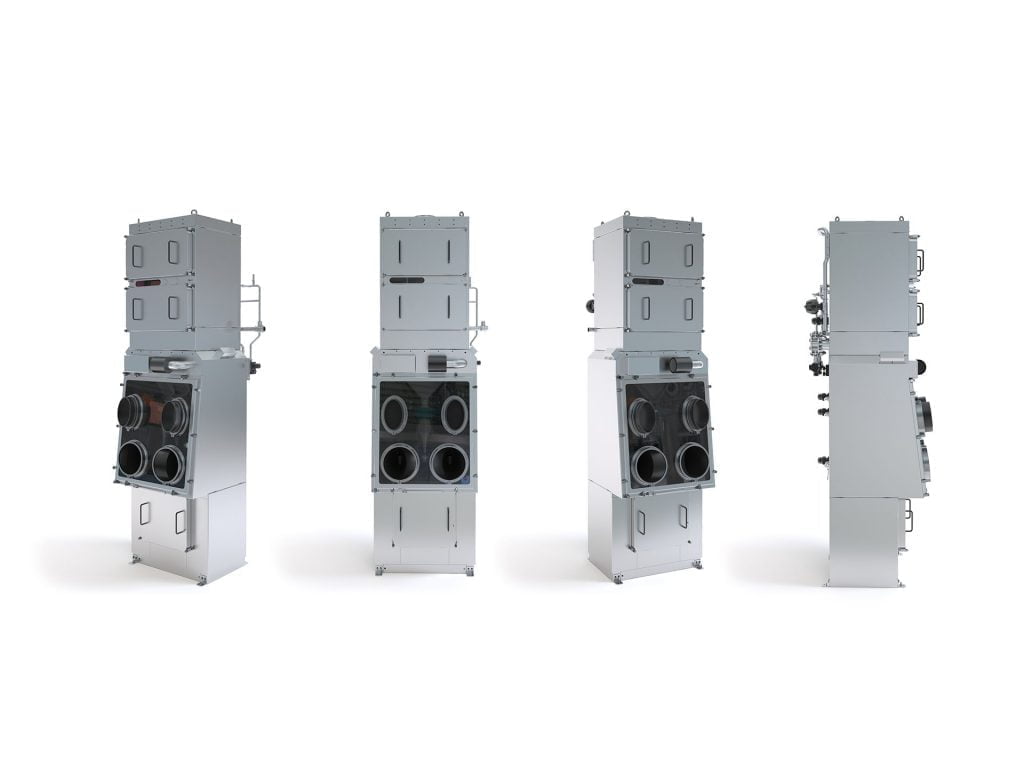

Efficient use of production space

Modern containment systems are often more compact and flexible, which means they take up less space. This enables more efficient use of existing production space and can reduce the need for costly expansions.

Requirements for filter systems for the pharmaceutical industry

A suitable containment system must meet specific requirements in order to effectively reduce production costs while ensuring safety and quality.

Advantages of an optimal filter system:

High-quality materials and innovative technologies

Filter systems should be made of robust, high-quality materials and use innovative technologies to ensure durability and efficiency. This reduces maintenance costs in the long term and increases the service life of the systems.

Flexibility and adaptability

Systems must be flexible and adaptable in order to meet different production requirements. This enables a quick changeover when changing products and a high level of investment security.

Comprehensive support and service

A reliable filter system should be accompanied by excellent customer support and service. This includes support with planning, installation, maintenance and optimization to ensure continuous operational readiness.

Regulatory compliance and certifications

Filter systems must meet all relevant regulatory requirements and have the necessary certifications. This makes it easier to comply with legal regulations and minimizes the risk of compliance problems.

Cost efficiency and sustainability

By reducing operating costs and increasing productivity, filter systems should offer a sustainable and cost-effective solution. This includes the efficient use of resources and the minimization of waste.

In summary, selecting an appropriate and efficient containment filter system may involve a high initial investment, but can significantly reduce overall production costs by lowering operating costs, increasing productivity and avoiding compliance risks. Careful planning and advice are crucial here.

Would you like to optimize your production costs while meeting the highest safety and quality standards? Contact us today to find out more about customized filter systems for your pharmaceutical production. Let’s work together to increase the efficiency and sustainability of your processes.