Perfectly equipped throughout the entire lifecycle

Filter cells suitable from one source

At the heart of our filter systems are the high-quality HEPA filters that we develop and manufacture in our own production facility in Altenstadt. These HEPA filters are the basis for our ability to offer first-class solutions in dedusting and air filtration, always with an optimum price-performance ratio and short delivery times in mind. Every HEPA filter undergoes a rigorous testing and certification process at our factory to ensure that it meets the high quality requirements and is individually tailored to the specific needs and requirements of our customers.

We also offer innovative cleaning systems to increase the efficiency and extend the service life of our HEPA filters. These systems make it possible to regenerate the filter elements of our systems without the need for a complete shutdown. By dividing the filter surface into several independent modules, each element can be individually removed from the filtration process and cleaned. This procedure ensures continuous operability and maximizes the service life of each HEPA filter.

By integrating such filters into our systems, we ensure that our customers benefit from consistently high filtration performance. The modularity and individual adaptability of our systems guarantee a high degree of flexibility and efficiency to meet the most diverse requirements in various industries. Our customers rely on the quality and performance of our HEPA filters, which play a key role in the purity and quality of the air in their premises.

We are happy to advise you

Get in touch with us

Timo Grieshaber

Containment accessories

Everything you need for your containment requirements

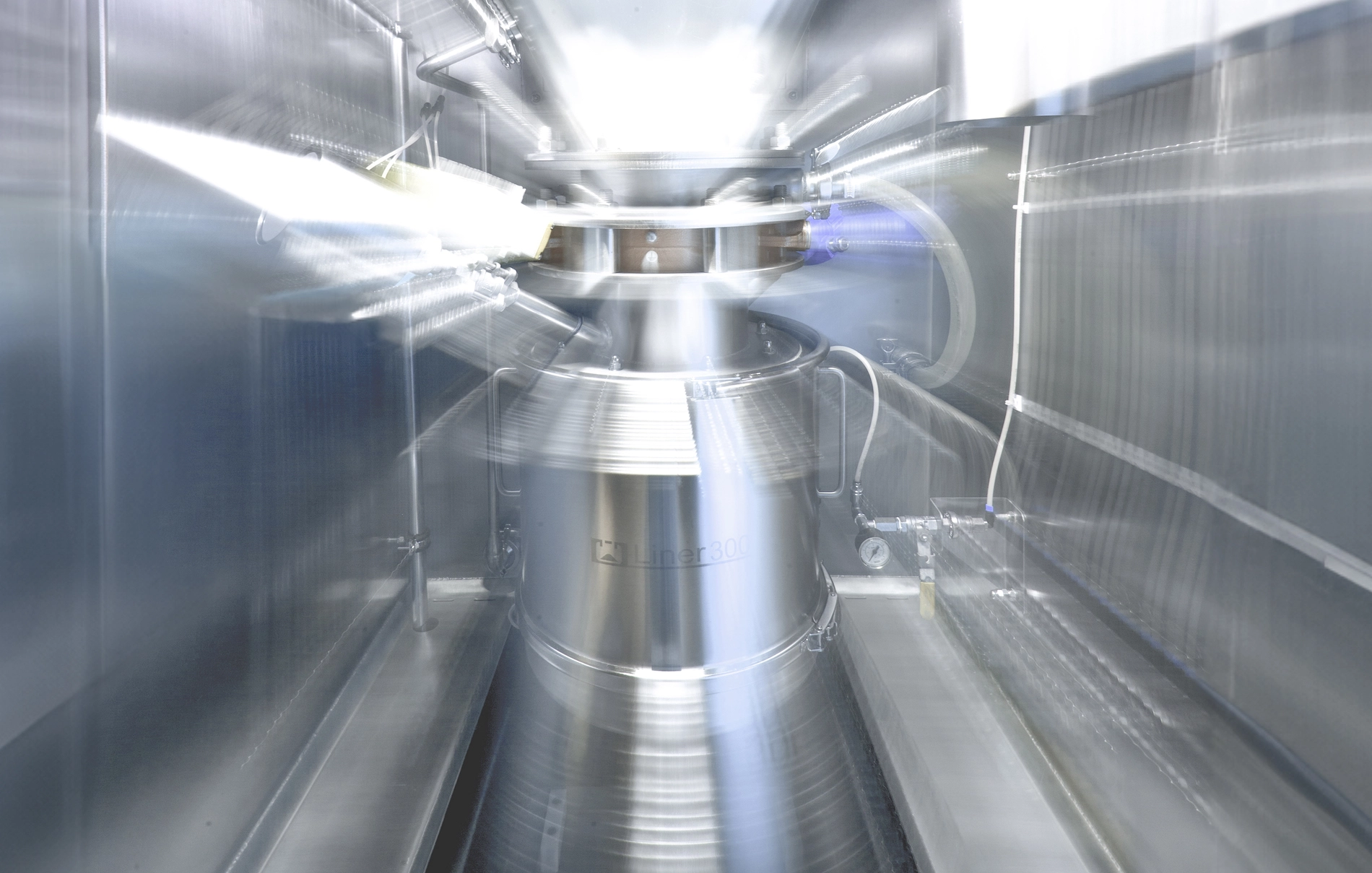

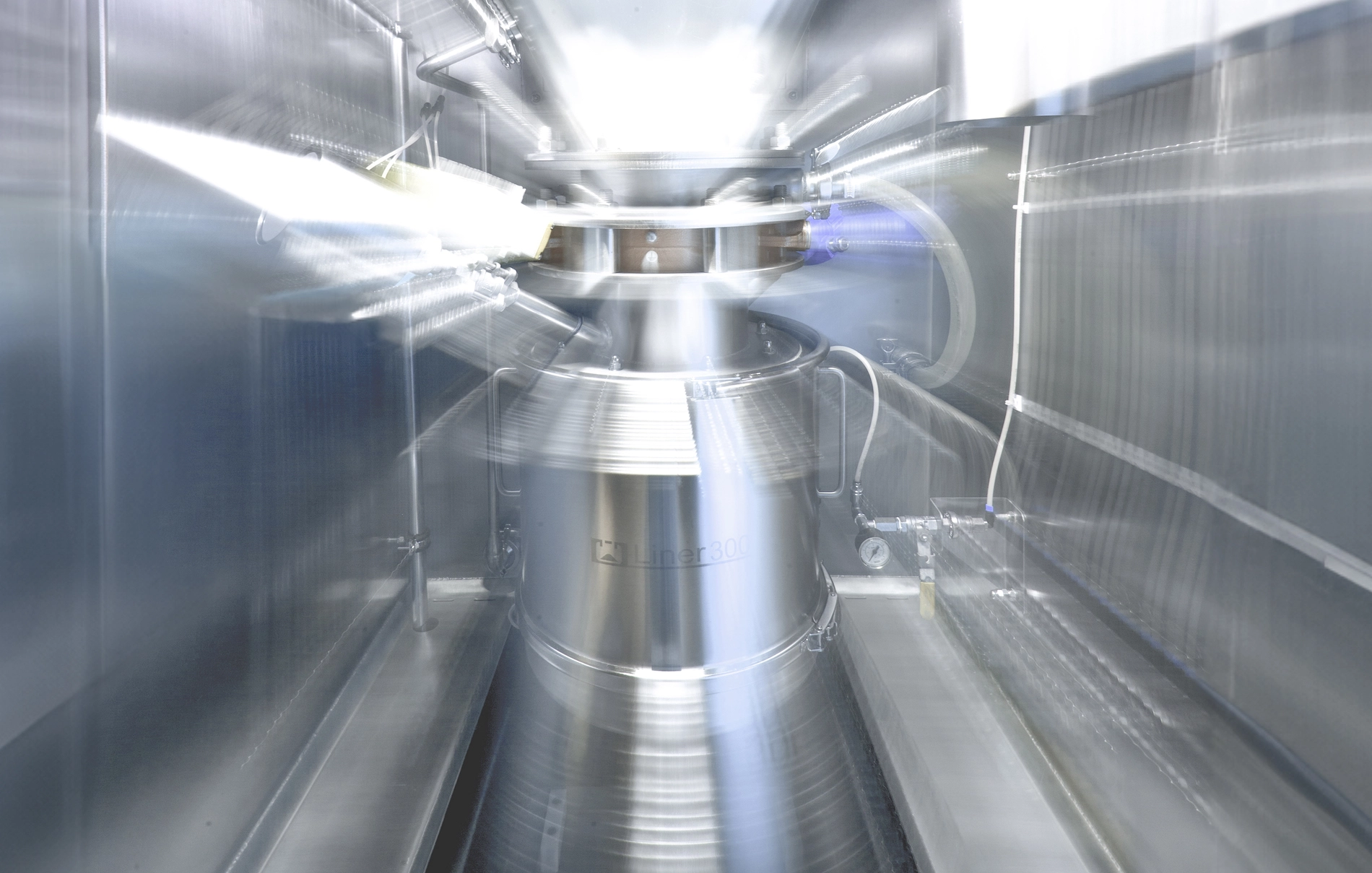

The pharmaceutical and chemical industries place particularly high demands on filter technology in production due to the use of highly contaminated substances. That is why we protect the working environment from harmful dusts not only during normal operation. We also ensure safe and contact-free disposal of highly active substances during maintenance and servicing work. Our systems meet the stringent requirements for safe OEB 6 operation.

This is ensured by a dust-free protective bag change by means of a safe-change system as well as primary filter (working filter) and secondary filter (safety filter). For the most stringent requirements, we also offer systems with the “Wash-in-Place” (WIP) cleaning system or a “Restricted-Access-Barrier-System” (RABS).

You need

Technical

Support?

Our technology

for best protection of personnel and product

Learn more about our filtration, containment and explosion protection technologies.