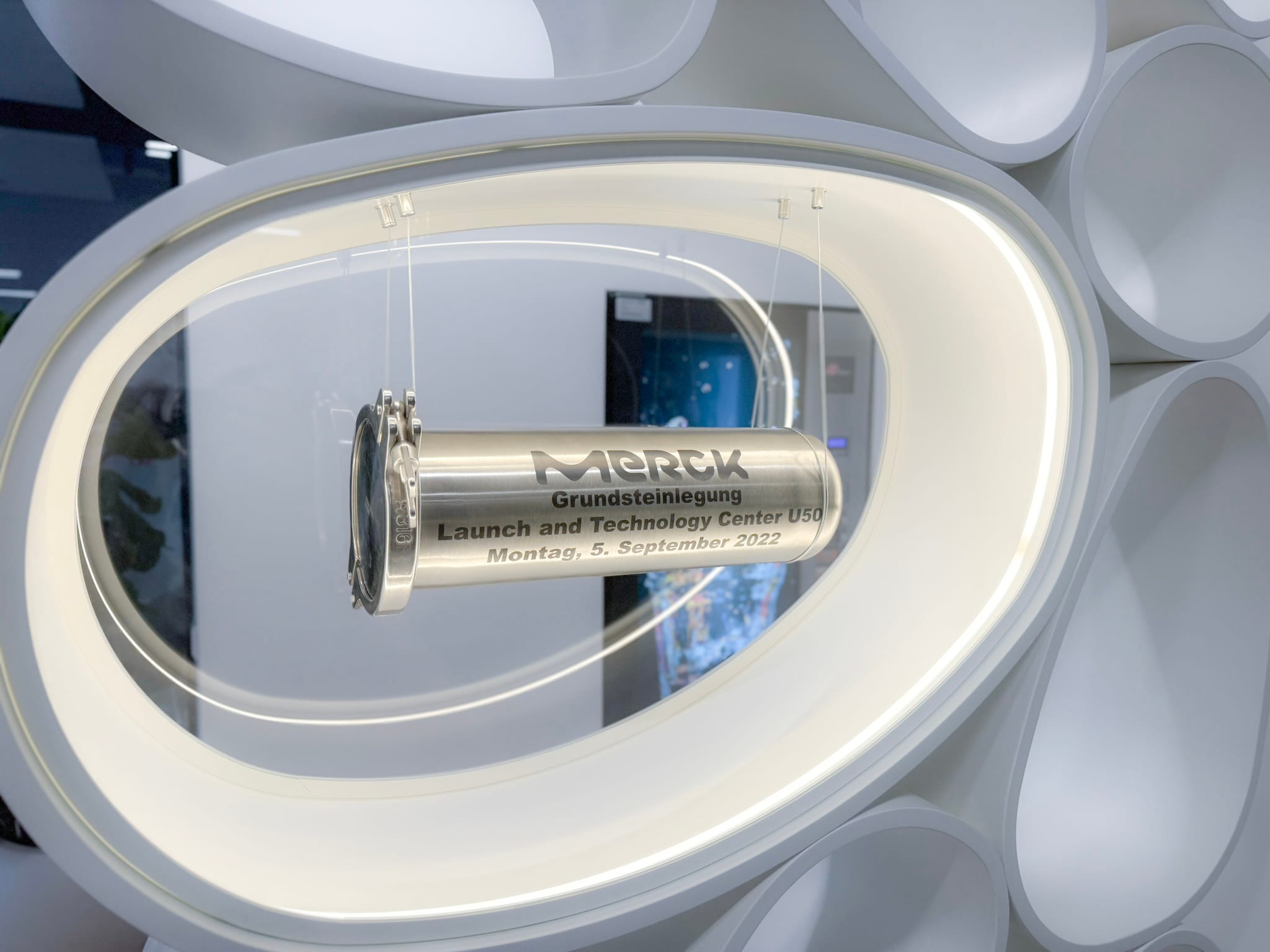

From laboratory to production: the Launch & Technology Center in Darmstadt

How Merck uses a flexible infrastructure and consistent containment to accelerate the path of new active ingredients into production

A building that organizes the transition from research to production

The new Launch & Technology Center on the Merck campus in Darmstadt is a building that already signals from the outside what it was designed for: Structure, precision and clear function. Behind the understated architecture, the 13,900 square metre building is a technical environment that reorganizes the transition from research to production. Each area is designed to seamlessly transfer different pharmaceutical projects into scalable manufacturing processes.

Inside, the architecture promotes rather than restricts work processes. Clean room areas, technical zones and laboratory areas are interlinked in such a way that defined flows of materials and people are created. Media channels and supply systems run through the building like an invisible line and connect the areas to form a functional overall system. Even before the first system goes into operation, it is already clear how flexibly the infrastructure is designed: connection points, modular rooms and clearly separated functional zones enable future process chains without having to fundamentally change the building.

The cleanroom windows reveal the areas where highly active substances will later be used. This is where processes are to take place under the strictest containment requirements. The rooms appear reserved, but their technical significance is clear: creating reproducible conditions, ensuring safety and reliably mastering variable process requirements.

The supply technology also meets this requirement. A geothermal energy system, photovoltaic surfaces and optimized waste water treatment are integral components of the overall concept. Sustainability is not an add-on here, but part of the building’s technical logic.

This means that the Launch & Technology Center is not a rigid production environment, but a system that is designed for changeability. A building that can accommodate different active ingredients, different processes and new requirements – and always follows the same premise: controlled conditions, clear structures and maximum safety.

Technology & equipment at a glance

Flexibility

The Launch & Technology Center is designed as a technical platform that can accommodate a wide variety of active ingredients and processes without requiring structural changes to the building.

High containment

Integrated filtration

Digital connection

Technical systems have digital interfaces for recording operating and process data and support documentation and transparent system monitoring.

Architecture for active ingredients yet to be discovered

The particular challenge of the Launch & Technology Center is that it was not built for a single active ingredient or a clearly defined process chain. Instead, it must be able to accommodate a variety of possible scenarios – from early development quantities to production batches close to the market, from moderately effective substances to highly potent active ingredients with strict containment requirements. The building is therefore less a classic production facility than a technical platform that has been deliberately designed to accommodate changing requirements.

This openness places extraordinary demands on architecture and technology. Containment, GMP and ATEX are not selective requirements here, but basic principles that characterize the entire structure.

Rooms must be able to support different safety levels and surfaces and interfaces must be completely cleanable in order to reliably prevent cross-contamination. At the same time, access points, airlocks and maintenance areas are designed in such a way that interventions remain controlled and safe – regardless of which substances are being processed.

To enable this degree of variability, the building follows an infrastructure logic based on clear separations and reproducible conditions. Technical zones and clean room areas guide material and personnel flows precisely, while media channels and supply points enable the integration of new process modules without having to intervene deeply in the structure. This creates an environment that meets the highest safety standards and at the same time offers the flexibility to safely process active ingredients with completely different properties.

Filter systems as an integral part of the process

In the Launch & Technology Center, the filter systems are an integral part of the cleanroom architecture. Each system is located directly in the wall – precisely at the points where product flows occur: at the fluidized bed, the tablet press and the coater. This proximity to the process follows a clear technical logic: filtration intervenes where particles are created and ensures that even highly active dusts remain safely contained under OEB 6 conditions. integration into the cleanroom places high demands on the design and material management. All components must be fully accessible, cleanable without residue and validatable so that product changes are possible without the risk of cross-contamination. Surfaces, sealing interfaces and piping are designed in such a way that cleaning processes can be carried out and documented reproducibly – a key aspect in an environment that has to accommodate changing active ingredients and variable process chains.

As a direct supplier and system partner, we were involved in the planning right from the start. Together with the customer, suitable systems were developed for the respective process steps – systems that fit precisely into the cleanroom architecture and at the same time meet the technical requirements for containment, cleanability and operability. The design of the product-carrying pipelines was particularly challenging: They must be completely drained, safely accessible and cleanable down to the last detail without breaking through the structural framework. The solutions designed for this purpose allow complete and validatable cleaning, even for highly active substances, and explosion protection also played a key role alongside containment and cleaning. As many powdered active substances can generate potentially flammable atmospheres, the filter systems and relevant system components are designed in accordance with ATEX criteria. Electrostatic charging, possible ignition sources and constructive pressure relief were already taken into account in the planning phase and integrated into the system architecture.

In addition, there are digital interfaces that provide the system status, filter performance and relevant process data in real time. This data not only enables transparent documentation, but also supports predictive maintenance concepts and integration into the higher-level building management system. This creates a technological environment in which filtration is not a downstream function, but a precisely coordinated component of the process chain – directly on the product, directly in the cleanroom and directly responsible for safety, cleanability and process control.

Would you like to know how our filter systems can make your processes safer and more efficient?

Get in touch with us

Sustainability as a technical guideline

Sustainability is not an additional requirement at the Launch & Technology Center, but part of the basic technical concept. The building was designed in such a way that energy efficiency, resource conservation and process reliability are not separate goals, but support each other. Geothermal energy, photovoltaics and intelligent water management form the infrastructural basis; in addition, there are systems that make it possible to precisely record the energy requirements of individual process steps and continuously monitor their efficiency. The filter systems are also integrated into this concept: Pressure losses, service life and cleaning cycles can be digitally evaluated so that the systems always work in the optimum operating range and unnecessary consumption of resources is avoided.

At the same time, the high cleanability of the equipment makes a significant contribution to sustainability. Processes that can be cleaned reproducibly and residue-free not only reduce the risk of faulty batches, but also the consumption of cleaning media and the amount of water required. Every complete cleaning therefore not only means safety, but also efficiency – both in operation and in validation.

The Launch & Technology Center demonstrates how modern pharmaceutical architecture can develop when flexibility, safety and sustainability are considered together. The building is not designed for a fixed active ingredient, but for the ability to adapt to new requirements. This is precisely its significance for the future: it creates a framework in which new generations of active ingredients can be developed under controlled conditions – regardless of how different they may be.

The close integration into the cleanroom architecture, digital networking and consistent focus on safety and cleanability show what technological solutions must look like if production environments are designed for long-term changeability.

A project with an impact beyond the immediate process

The Launch & Technology Center shows what pharmaceutical production environments can look like when flexibility, safety and technical precision are considered together from the outset. The architecture is designed to process a wide variety of active ingredients under stable, reproducible conditions while meeting the highest requirements for containment, cleanability and documentation. This creates a structure that is not tied to a fixed process, but can accommodate new processes quickly and in a controlled manner.

In this form, the LTC becomes a model for how modern manufacturing processes can be further developed. The combination of integrated cleanroom technology, digital transparency, energy-efficient infrastructure and flexibly usable process zones creates an environment that remains sustainable in the long term – even if future active ingredients pose new challenges. The project shows that production buildings must not only respond to current needs, but should also be prepared for a future whose requirements are not yet fully known.

OTHER INTERESTING TOPICS

Focus on nitrosamines: containment and filter solutions for maximum pharmaceutical safety

Nitrosamines have been a key quality and safety issue in the pharmaceutical industry for several years. The discovery of nitrosamine-containing...

Retrofit containment solutions for existing systems: Optimize safety and compliance economically

Pharmaceutical and fine chemical companies must regularly adapt their production environments to new regulations.Stricter GMP requirements, the...

Digitalization in filtration technology

Digitalization has long since arrived in production-related areas of the pharmaceutical industry - with a clear goal: greater efficiency, safety and...