...safety installed...

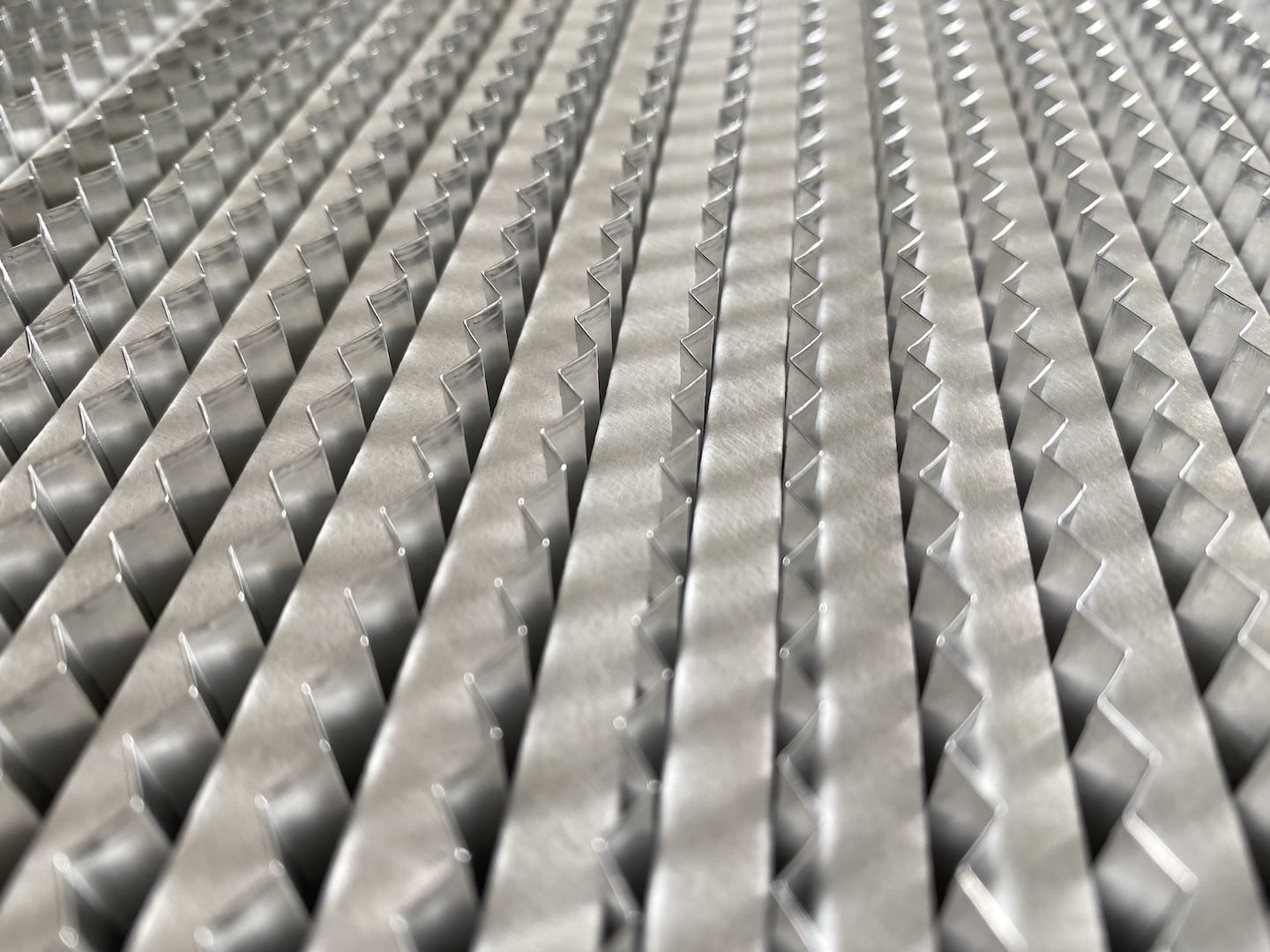

Filter systems for capsule fillers

Reliable filter technology for maximum product safety and optimum protection of the operator and process.

Precise filtration for your capsule fillers

Maximum efficiency and protection thanks to proven filter technology for pharmaceutical applications

Our filter systems for capsule fillers offer maximum safety and reliability in pharmaceutical production environments. Precisely matched filtration systems effectively separate dust, minimizing the risk of cross-contamination. The systems meet all GMP requirements and can be flexibly integrated into existing production lines, ensuring consistent quality and safe processes.

The systems are characterized by a long filter service life and easy maintenance. Self-regenerating HEPA filters ensure continuous filtration and reduce downtimes. Optimized airflow and energy-efficient components help to conserve resources, while the containment design offers maximum safety for the operator and product.

Thanks to their modular design, our systems can be adapted to different production sizes and speeds. Manufacturers benefit from reliable filtration, efficient operation and a future-proof solution for demanding capsule production.

We are happy to advise you

Get in touch with us

Simone Knasel

Safe containment for capsule fillers

Reliable protection of operators and product with highly active substances

Filter systems for capsule fillers

Advantages

- Modular design for system-specific adaptation of size and air volume.

- High separation efficiency for fine coating dusts

- Maximum operational safety

- Maintenance-friendly design with quick filter changes

- Continuous and discontinuous operation

- Plant in dust-tight or gas-tight design

- DEHS measuring points for qualification of the safety filter stage

- GMP-compliant design

OUR FILTER SYSTEMS FOR coaters

The cleanable filter system

Mobile small dust extractor for flexible use

Filter system for low dust loads

The cleanable filter system

Mobile small dust extractor for flexible use

Filter system for low dust loads

Technologies

Filtration

Containment

Explosion protection

From one source

Safety

is our mission

You want to learn more?

Contact us!

Contact

Information on

Technologies