...safety installed...

Efficient filtration for fluidized bed processes

Protect your production environment with innovative filtration solutions for fluidized bed processes.

Fluidized beds in the pharmaceutical industry

Maximum safety and efficiency thanks to cleanable HEPA filters

In the pharmaceutical industry, fluidized beds are essential for processes such as drying, granulation, coating, agglomeration and mixing. The intensive air flow ensures that powders are processed efficiently, which guarantees consistent product quality. However, this creates a high dust load, which poses risks for the product, personnel and the environment.

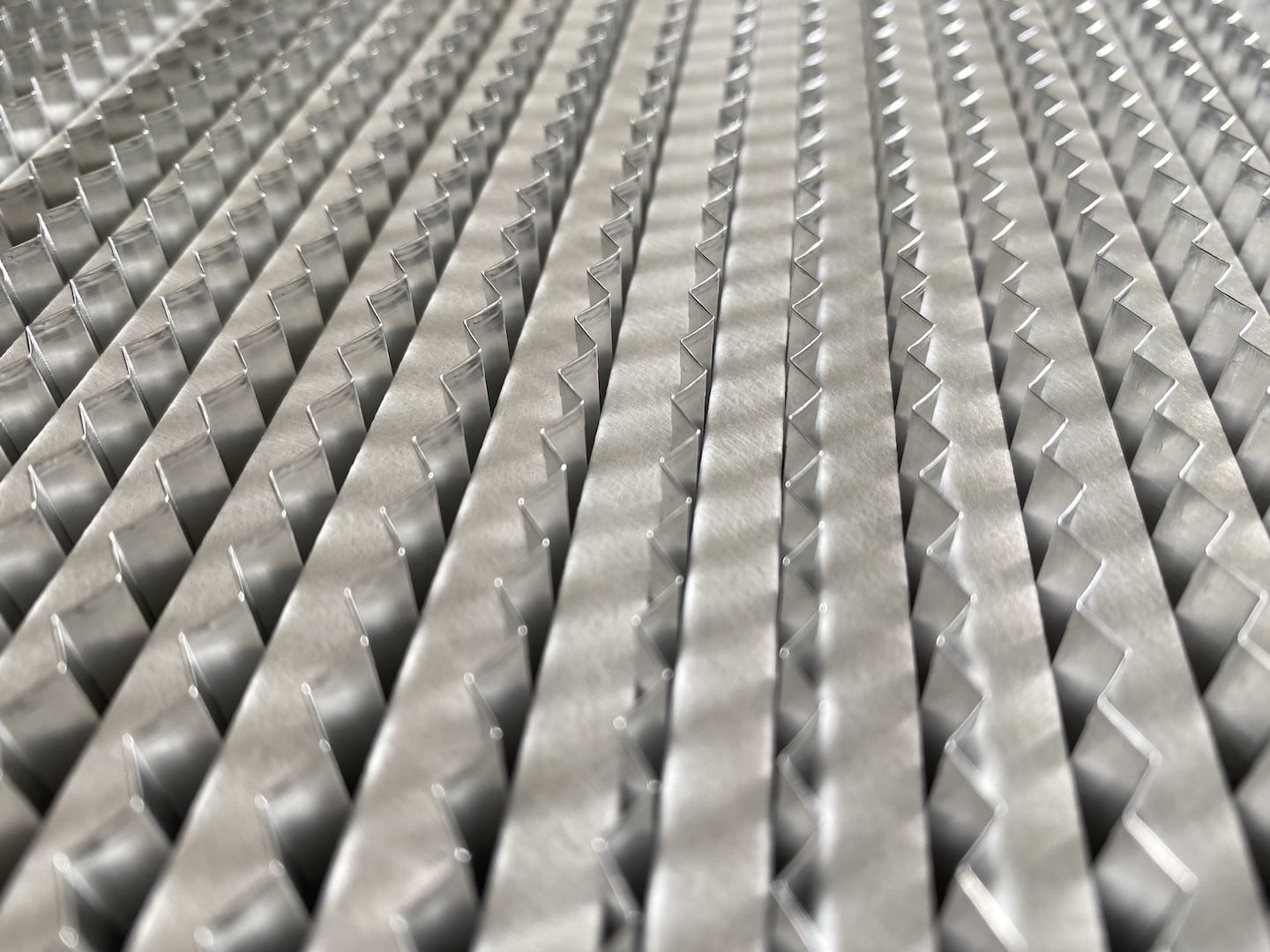

HEPA filters are used to minimize these. These filter at least 99.95 % of all particles from 0.3 micrometers and meet important regulations. Cleanable HEPA filters are particularly effective, offering a longer service life and lower operating costs thanks to regular cleaning. They protect employees from highly potent substances, prevent cross-contamination and extend the service life of downstream systems.

This ensures an efficient, safe and legally compliant production process.

We are happy to advise you

Get in touch with us

Ralf Kunert

rkunert@het-filter.de

HET filter systems for fluidized beds

Reliable filtration for maximum process reliability

Filter systems for fluidized beds

Advantages

- Flexible adaptation to different vortex layers

- Highly efficient dust separation

- Maximum operational safety

- Cleaning system for backwashing the primary filter by means of cleaning cylinder

- Continuous and discontinuous operation

- Plant in dust-tight or gas-tight design

- DEHS measuring points for qualification of the safety filter stage

- GMP-compliant design

Cleanable HEPA filters, which extend their service life through regular cleaning, are particularly advantageous. This reduces operating costs, as filter changes are required less frequently, and ensures a stable, uninterrupted production process. In addition, these filters provide effective protection for downstream systems such as pipelines, fans and heat exchangers by preventing dust deposits. They help to stabilize the air flow, ensuring consistent production conditions.

Another key aspect is the protection of employees. HEPA filters prevent the release of hazardous substances and ensure compliance with OEL limits, especially when processing highly potent active ingredients. Cleanability also promotes sustainability, as the reuse of filter media saves resources and reduces disposal costs. This makes them an economical and environmentally friendly solution for modern pharmaceutical production processes.

OUR FILTERING SYSTEMS FOR WIRELSCHICHTER

The cleanable filter system

Mobile small dust extractor for flexible use

Filter system for low dust loads

The cleanable filter system

Mobile small dust extractor for flexible use

Filter system for low dust loads

Technologies

Filtration

Containment