Filtration

State-of-the-art filtration processes ensure clean air.

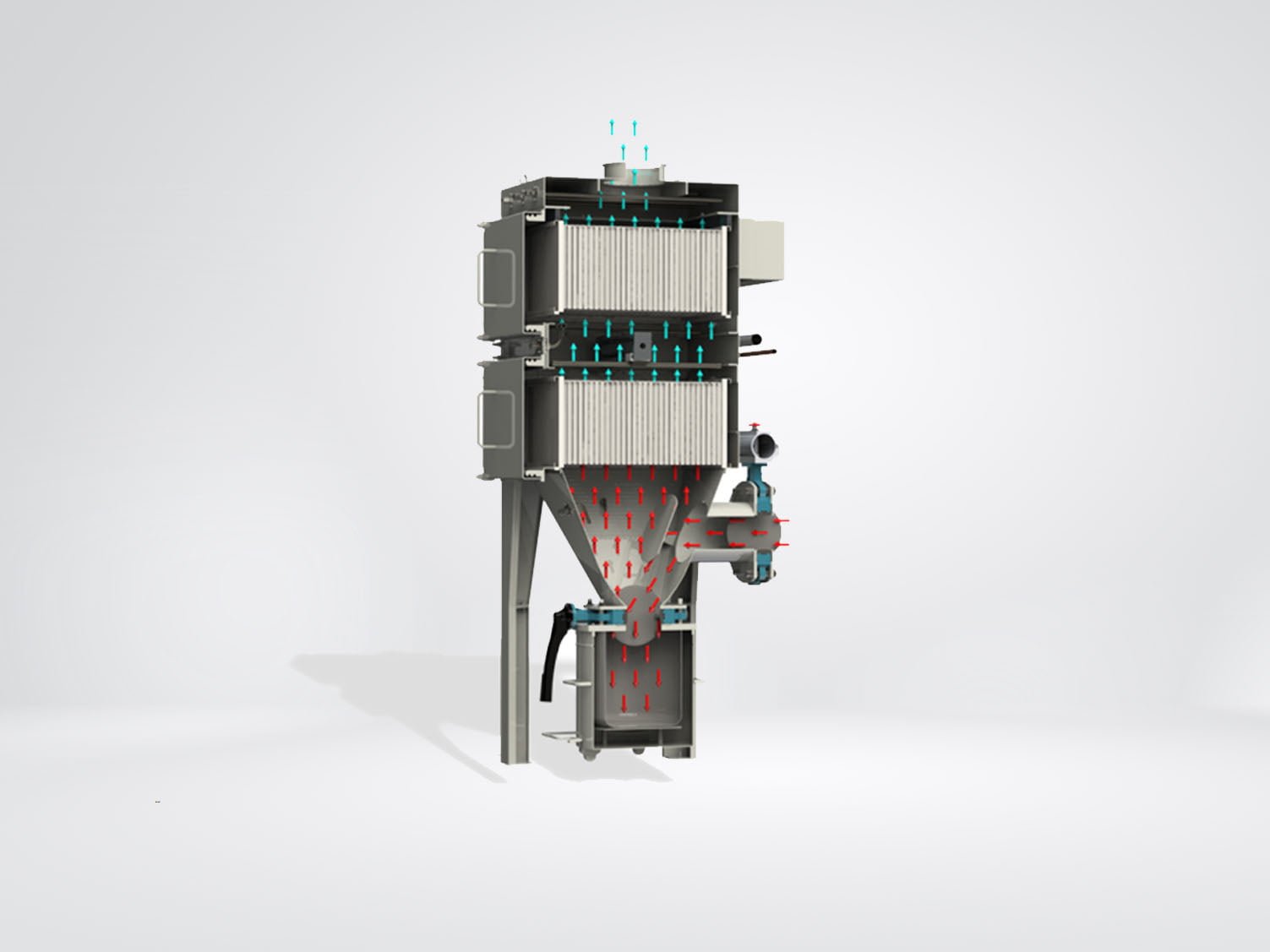

The filtration principle

Using the example of a HETdynamic

In our advanced filtration system, the dust-laden exhaust air first enters the system via the raw gas duct, where an effective filtration process begins.

Coarse filtration ensures that large and heavy particles sink into the dust container, making disposal easy. This first stage of filtration is crucial in order to reduce the load on the subsequent finer filters.

In the next phase of filtration, the primary filter plays a decisive role. It is specially designed to filter fine dust from the air. These particles remain in the filter medium while the purified air enters the clean gas chamber, which is an essential step in the air purification process. The efficiency of this filtration step is of the utmost importance, as it plays a key role in determining the quality of the discharged air.

In order to integrate an additional safety level into our filtration system, a secondary filter is used, which acts as a safety filter. This comes into play if there is a filter breakthrough in the primary filter. In such a case, the secondary filter takes over the filtration task to ensure that no unwanted particles leave the system. It maintains filtration until the primary filter is replaced, thus guaranteeing continuous and reliable cleaning of the exhaust air. This multi-stage filtration strategy ensures efficient and reliable purification of the exhaust air and underlines our commitment to high-quality air purification processes.

…safety installed…

THE FILTRATION PRINCIPLE

The principle

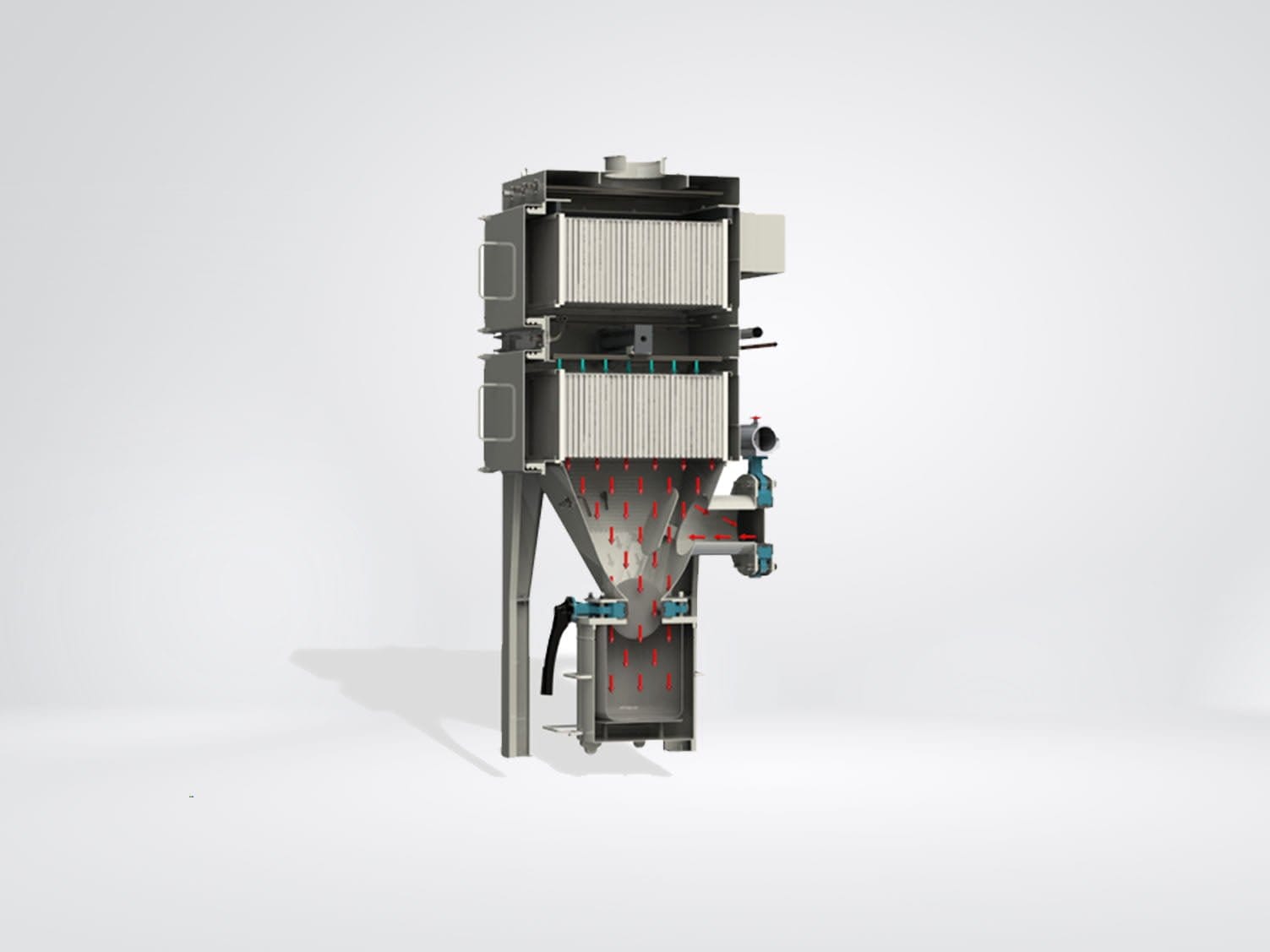

Our cleaning

Our filter unit HETdynamic can be additionally equipped with the function of cleaning. Here, a cleaning cylinder travels above the primary filter cell and blows compressed air in the direction of the dust funnel. The dust particles detach from the filter medium and sink into the dust collection container.

During cleaning, the raw gas flap is closed and interrupts the flow through the filter chamber. This decouples the filter module from the overall system and thus prevents backwashing of the dust into the raw gas duct.

For 24/7 operation, our filter systems can be designed for continuous operation, without interruption of dust removal. Thus, a lower filter area load is already selected during the design and the filter area is divided into several modules.

This allows each of these elements to be decoupled and cleaned from the overall process. In this way, the filters remain in use permanently due to the change operation and continue to achieve a long service life.

HET Filter systems

Explosion protection

For maximum safety

learn more

Containment

Safe protection against hazardous substances

learn more

Things to know

Everything about filtration and dedusting

Learn more about our technologies and many other exciting topics.